John Deere N543F

Separate Fertilizer Placement (SFP) Air Drill

- Adjust down pressure with TruSet™ In-Cab downforce

- See the flow of seed & fertilizer from the cab with RelativeFlow™ blockage monitoring

- Quick Change Blade enhancement of the ProSeries™ Opener reduces change time by up to 45%1

- Accurate seed placement & emergence with TruSet™ in-cab "closed loop" downforce pressure control

Features

To win big in small grains, it takes a seeding solution that superseeds your expectations. John Deere delivers with a complete line of everything you need – and the sizes you want – to seed for success. Air-hoe drills. Commodity air carts. No-till air drills. Openers. Fertilizer attachments. Central commodity systems. Box drills. Plus precision ag technology to stretch your productivity to higher levels. But it’s far more than iron and technology. It’s the exceptional agronomic know-how and unsurpassed dealer support in all phases of production to keep you running. With our latest additions to equipment and openers, our seeding solutions deliver the next-generation performance you need to help you reach the full potential of each seed. That’s our commitment to you.

With RelativeFlow Blockage sensing, operators can see the flow of both seed and fertilizer from inside the tractor cab. Sensors on all secondary hoses monitor the relative product flow row to row, giving you a better view of the flow rate of both seed and fertilizer from the cart to the opener from inside your tractor cab. This technology can help you identify any problems before a potential blockage occurs.

RelativeFlow Blockage is available in all run configurations on the following models (all widths):

- H500

- H500F

- P500

- P600

- N500

- N500F

- N500C

- 730LL

RelativeFlow Blockage is compatible with hydraulic drive carts: model year 2014 and newer 1910, all 19,381.5-L (550-bu) 1910 Carts, and C650 and C850 Air Carts.

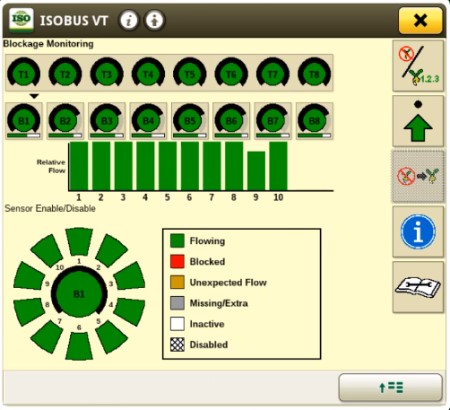

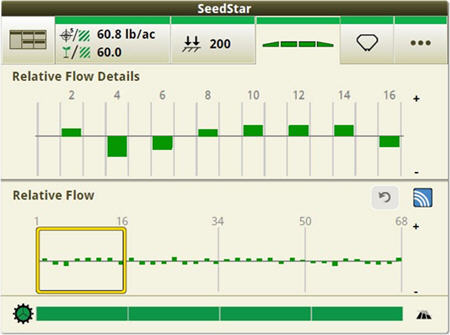

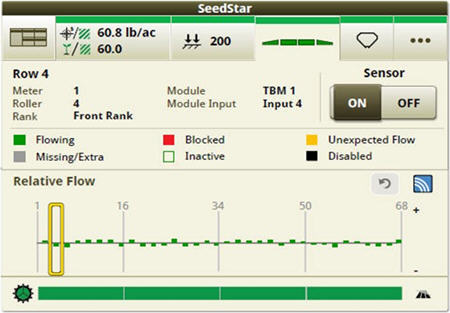

Below are the Gen 4 display screens for the blockage monitoring system. For complete details and information, see the owner’s manual.

Blockage monitoring screen on Gen 4 display

Blockage monitoring screen on Gen 4 display

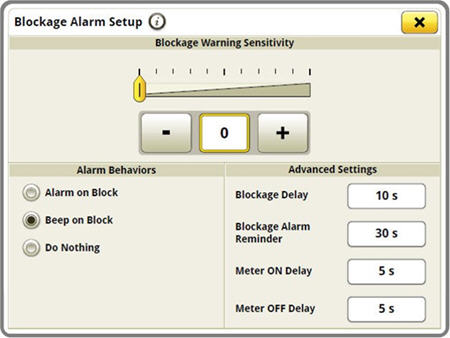

The RelativeFlow Blockage sensing chart shows the amount of flow through each sensor on the selected tower. Sensitivity for the blockage system can be adjusted if desired, as shown below.

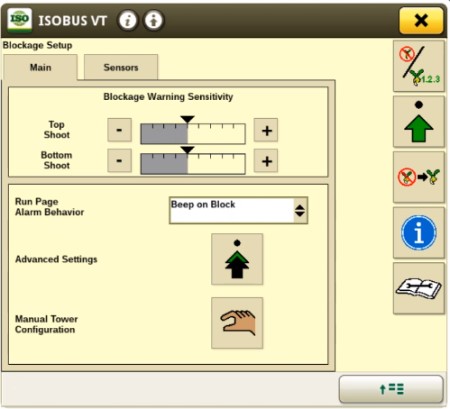

Blockage Setup screen on Gen 4 display

Blockage Setup screen on Gen 4 display

Blockage warning sensitivity allows the producer to set and change the sensitivity of the sensors to meet their preferences and varying crop/fertilizer types. Increasing the sensitivity means the system is more likely to show a false blockage, while less sensitivity means the system is more likely to miss a blockage.

Multiple run-page alarm behavior options are available for selection.

Blockage monitoring screen on Gen 4 display

Blockage monitoring screen on Gen 4 display

Below are the Gen 4 display screens for the blockage monitoring system on the N500C.

For complete details and information reference, the owner’s manual.

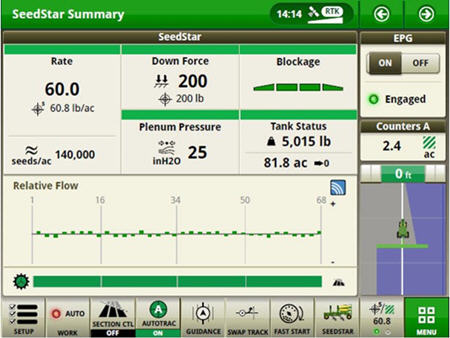

RelativeFlow Blockage configured run page

RelativeFlow Blockage configured run page

The SeedStar™ system run page displays the five major run settings. Clicking on any of the tiles will take an operator to that specific page (shown below).

Operators can zoom into flow details by meter section when selecting blockage tiles

Operators can zoom into flow details by meter section when selecting blockage tiles

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

Operators can zoom into the row level to access row/sensor information and turn a sensor on/off independently

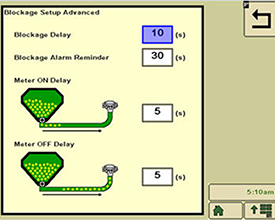

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage sensitivities and alarm delays are all set up on one easy-to-navigate screen

Blockage alarm delays can be set up by clicking on the advanced settings button from the blockage set-up screen.

- A blockage delay is how long a blockage should occur before an alarm is sounded.

- The blockage alarm reminder is how often the alarm should sound when a blockage occurs.

- The meter on delay is the time from when the meter is turned on until the blockage sensor should start monitoring for blockage.

- The meter off delay is the time from when the meter is turned off until the blockage sensor should start monitoring to verify no flow.

For more detailed information, see the owner’s manual.

Air tools with RelativeFlow Blockage are not compatible with 1910 air carts with ground drive.

Down pressure adjustment for seed or fertilizer

Down pressure adjustment for seed or fertilizer

Setting the opener down pressure is convenient and easy to adjust.

For 9.1-, 11.0-, 12.2-, and 13.1-m (30-, 36-, 40-, and 43-ft) widths the down pressure on the front fertilizer rockshaft is adjusted independently of the middle and rear seed opener rockshafts. Simply dial in the required pressure using the knobs.

The seed opener pressure gauge face is color coded to provide a guide for normal pressure operating ranges.

Valve block

Valve block

The valve has two internal checks to reduce possibility of damage to valve when charging the system.

The down pressure cylinder is connected to live hydraulics and extends or retracts to maintain uniform down pressure on openers.

This system is compatible with either closed center or pressure flow compensated tractor hydraulic systems.

IMPORTANT: Tractors with open-center hydraulics require an open-center kit with change valve (order code 6505 to make the air drill compatible). The open-center application does not provide an opener flexibility feature.

If you need high rates in your operation, AirPower 2 delivers. With the dual fan system, you get twice the fans than the original AirPower. Plus, each fan is larger than before. So when you need that additional power to generate a higher level of input flow, AirPower 2 has the capability to deliver what you need. And the fan housing is cast aluminum, making it lighter in weight, but more durable than ever before. You can trust your fan system will stand the test of time.

Dual fan design

John Deere AirPower 2 system uses two separate, high-capacity fans – one for top shoot, one for bottom shoot. Using both fans can deliver a total of 550 pounds (249.5 kg) at 5.5 mph at 15 degree slope of material per acre, precisely metering product into the primary air stream. The results: Greater consistency across the entire drill, more uniform seed emergence, more even flowering and canopy development, and greater yields.

Air Power 2 fan system

Air Power 2 fan system

Enhanced air seeding performance would not be possible without the updates to the 15,152.8-L (430-bu) and 19,381.5-L (550-bu) 1910 and C-Series Air Carts. For the wider seeding width, more fan capacity has been added.

Air Power 2 provides two independently controlled fans – one for seed and one for fertilizer. Along with large, 76.2-mm (3-in.) primaries, more accurate delivery rates are possible across the full width of the seeding tool, from opener to opener. Plus, Air Power 2 allows growers to deliver high rates under field operating conditions – up to 40 percent more product delivery per primary compared to the single-fan system.

Dual fans are required for tow-between and tow-behind carts on the 23.2-m (76-ft) P576 and 18.3-m (60-ft) N560F models along with the eight primaries. Each fan will direct air to one set of primaries. Two selective control valves (SCVs) are required for the fans. The fan speed will be controlled through the SCV flow control.

Air Power 2 will also be compatible with the 17.1-m (56-ft) P556 and 23.2-m (76-ft) P576 Air Hoe Drills, as well as the 13.1-m (43-ft) N543F and 18.3-m (60-ft) N560F Disk Drills, plus the 15.2-m (50-ft) and 18.3-m (60-ft) 1890 models. An option is available for stainless-steel primaries to resist corrosion from high fertilizer rates.

C-Series Air Cart

C-Series Air Cart

There is a slide at the meter to choose bottom or top shoot for each meter. There is also a valve on the tank pressure system to choose top or bottom shoot. This same valve is used to adjust the amount of air to the tank to create the proper pressure differential.

Tank pressure valve

Tank pressure valve

The arrow on the valve handle should be pointing to the top of the range for the top shoot and the bottom of the range for the bottom shoot. If the tank will not be in use, set the pressure valve to the middle setting to not pressurize the tank. The operator should use the gauge to find the correct setting. An electronic pressure sensor will send a warning to the display if the tank pressure differential is out of range.

If pressure is in the green operating range, the tanks are sealed and operating correctly. The electronic pressure sensor is located behind the mechanical gauge on the side of the cart.

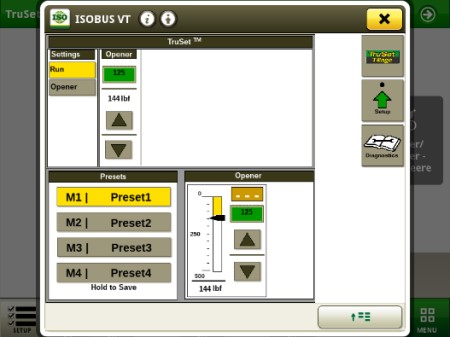

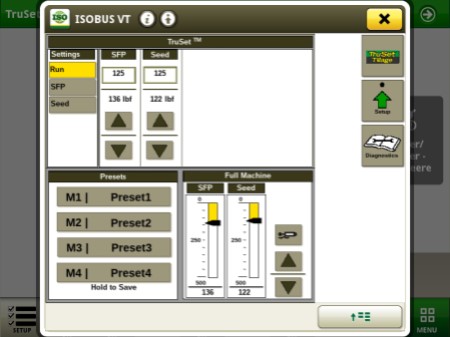

TruSet downforce allows operators to set downforce pressures from inside the cab. Downforce can easily be changed by the push of a button as soil conditions vary. Proper downforce is directly related to a consistent seeding depth, which leads to improved even emergence, plant density, and maturity. The range of downforce adjustability begins at 74.8 kg (165 lb) and tops out at 181.4 kg (400 lb).

TruSet screen on Gen 4 display for N500

TruSet screen on Gen 4 display for N500

TruSet screen on Gen 4 display for N500F

TruSet screen on Gen 4 display for N500F

Exclusive TruSet downforce control has taken adjustability on no-till John Deere seeding tools to a whole new level. Rather than using a valve on the tool, pressure control dials on the monitor let operators make incremental adjustments conveniently from the Gen 4 display inside the tractor cab. This also saves time and makes it easier to adapt to changing field conditions.

Seeding tool compatibility:

- N500

- N500F

NOTE: It is recommended that 15.2-m and 18.3-m (50-ft and 60-ft) machines use power beyond to run TruSet.

Display compatibility:

- Gen 4 displays

- GreenStar™ 3 2630 Display

Competitive tractors do not require add-on components for TruSet to function properly.

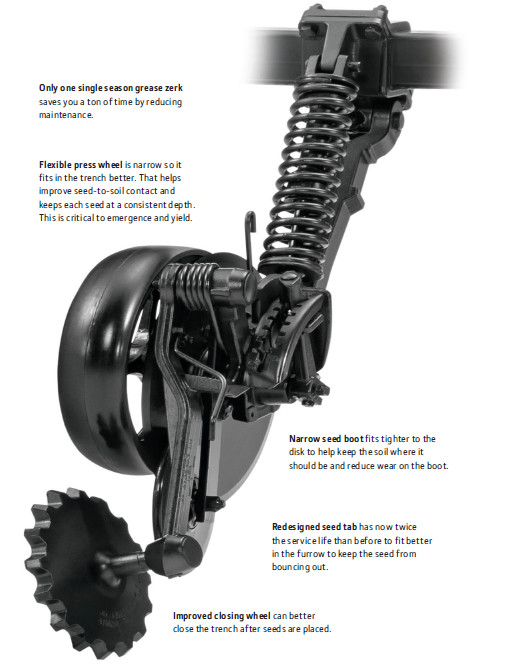

ProSeries Openers

ProSeries Openers

The ProSeries Opener is John Deere’s most advanced opener for your seed and separate fertilizer placement. When it comes to seeding precision, consistent seed depth, and uniform emergence in virtually all field conditions, you can superSEED your expectations with ProSeries.

Two of the three daily grease points were removed. The only remaining grease point is a yearly interval. The narrow seed boot travels behind the shadow of the blade, causing less soil disturbance. When attaching the boot to the shank, the bolt has been replaced with a flag pin. Now the flag pin is the wear point, not the casting, reducing overall maintenance. The seed press wheel is also redesigned; it has a narrow profile, a double-wall bearing, and is made of a flexible material. The quick-change blade feature reduces the time it takes to change each blade, saving time and money. Lastly, the seed tab is UV resistant and profiled similar to the trench. There is also the added option of the serrated closing wheel.

ProSeries Openers are in base equipment on all N500 and N500F Separate Fertilizer Placement (SFP), N500C, 1990 Central Commodity System (CCS™), and 1590 Air Drills.

The ProSeries Openers:

- Work not only in no-till conditions, but also in minimum or reduced-till conditions

- Provide 51 mm (2 in.) of free travel in the opener before spring down pressure takes over

- Benefit: allows the opener to move over uneven ground conditions and minimize the chance of the gauge wheels bulldozing soil in soft or mellow conditions

- The opener spring travels a maximum of 203-mm (8-in.) up or 150-mm (6-in.) down before the hydraulics react to uneven seedbeds

SFP Openers

SFP Openers

Separate fertilizer placement offers nutrient placement at a 5 or 7-degree angle

The 5-degree fertilizer opener:

- Is required for liquid and anhydrous (NH3) fertilizers

- Will also apply dry fertilizer

- Opens a smaller trench than the 7-degree opener

- Is better able to capture anhydrous and liquid fertilizer and seal fertilizers in the soil

Fertilizer tubes

There are four choices of interchangeable fertilizer tubes:

- Dry fertilizer tube to be used with 32-mm (1-1/4-in.) secondary fertilizer hose from the 1910 Cart

- Liquid fertilizer tube (for 13-mm [1/2-in.] i.d. hose)

- IMPORTANT: Using this tube for anhydrous may cause loss of retention.

- Dual fertilizer delivery tube – allows for placement of dry or anhydrous. If applying both simultaneously, the operator may need to provide a relief system to relieve air from dry tube for adequate anhydrous retention. Without air relief, the operator will need to adjust air plenum to restrict all airflow to SFP dry tubes when anhydrous is being applied

- Anhydrous tube (for 10-mm [3/8-in.] i.d. hose)

- Liquid or NH3 fertilizer metering/delivery system is not provided by the John Deere Seeding Group.

Key features of the SFP opener are:

- 457.2-mm (18-in.) opener blades operate at 5 degrees, resulting in a narrow trench with less soil disturbance

- Fertilizer tubes are interchangeable among dry, liquid, or anhydrous (NH3)

- Closing wheel assembly is closer to the fertilizer delivery tube; provides increased fertilizer retention

- Serrated closing wheels are base equipment on anhydrous openers and optional on liquid and dry openers

- NOTE: Closing wheels are recommended when dry soil conditions are common.

- Extended-wear (chrome alloy) fertilizer boots are standard equipment

- Choice of five different gauge wheels

- Depth adjustments in 6-mm (1/4-in.) increments from 13 mm to 89 mm (1/2 in. to 3.5 in.) deep

Opener furrow-closing wheel

The 25-mm x 305-mm (1-in. x 12-in.) cast closing wheel follows the press wheel to close the furrow, placing soil over seed or fertilizer after the press wheel secures the seed in the furrow.

- A double-row ball bearing to reduce wear is located in the arm of the closing wheel

- Mounted parallel to the furrow opener, the closing wheel can be adjusted laterally to allow running on top of the furrow for sandy or mellow soils or to side of the furrow for heavier soils

- Down pressure is adjustable from 11.8 kg to 19.5 kg (26 lb to 43 lb) (no tools and three adjustments)

- A grease fitting in the pivot arm provides free movement for the arm

SFP upgrade kit

SFP scrapers can bolt a sealing wing to the bottom of the improved anhydrous (NH3) retention by reducing outgassing. It is made of steel and has carbide titles brazed to the edges for long life.

- Parts: AA102150 and AA102151

The SFP opener closing arm spring will better hold the notched retention position. When selecting options for anhydrous fertilizer delivery, the SFP opener has a carbide sealing wing. The sealing wing agitates the trench sidewall and helps seal the top of the furrow with soil. This helps facilitate the binding of anhydrous ammonia to the soil, which reduces outgassing, keeps more fertilizer in the ground, and provides a boost to young plants.

| Group key | Component | Description | Quantity | Component unit |

| AA102150 | 03H2070 | Round head square neck bolt | 8 | PC |

| AA102150 | 03M7224 | Round head square short neck bolt, metric | 2 | PC |

| AA102150 | 14M7396 | Hex FL self-locking nut, metric | 2 | PC |

| AA102150 | A107506 | Special washer | 8 | PC |

| AA102150 | A116640 | Right-hand SFP scraper | 1 | PC |

| AA102150 | A116641 | Left-hand SFP scraper | 1 | PC |

| AA102150 | AA97059 | Left-hand NH3 sealing plate | 1 | PC |

| AA102150 | AA97060 | Right-hand NG3 sealing plate | 1 | PC |

| AA102150 | E55662 | Flange nut, 3/8 | 8 | PC |

| AA102150 | N283804 | Boron disk | 2 | PC |

Yellow rows are the actual parts. Everything else is hardware.

| Group key | Component | Description | Quantity | Component unit |

| AA102151 | 03H2070 | Round head square neck bolt | 32 | PC |

| AA102151 | 03M7224 | Round head square short neck bolt, metric | 8 | PC |

| AA102151 | 14M7396 | Hex FL self-locking nut, metric | 8 | PC |

| AA102151 | A107506 | Special washer | 32 | PC |

| AA102151 | A116640 | Right-hand SFP scraper | 4 | PC |

| AA102151 | A116641 | Left-hand SFP scraper | 4 | PC |

| AA102151 | AA97059 | Left-hand NH3 sealing plate | 4 | PC |

| AA102151 | AA97060 | Right-hand NH3 sealing plate | 4 | PC |

| AA102151 | E55662 | Flange nut, 3/8 | 32 | PC |

| AA102151 | N283804 | Boron disk | 8 | PC |

Yellow rows are actual parts. Everything else is hardware.

Upgrade your current 90 Series Opener to the ProSeries Openers by ordering a performance upgrade kit. Information on the ProSeries Opener can be found here.

Two kit offerings are available for seed openers, a two row (AA98693) and eight row (AA97392) kit. The breakdowns are as follows:

AA98693

| A105410 | Deflector, seed firmer tab | 2 pc |

| A107506 | Washer, special | 8 pc |

| A109343 | Seed boot, left hand | 1 pc |

| A109344 | Seed boot, right hand | 1 pc |

| A110307 | Closing arm spring, left hand | 1 pc |

| A110308 | Closing arm spring, right hand | 1 pc |

| A31869 | Locknut | 2 pc |

| AA88056 | Press wheel assembly | 2 pc |

| E55662 | Nut, 3/8 | 8 pc |

| N280653 | Washer | 2 pc |

| N283804 | Opener disk | 2 pc |

| N283976 | Nut, U-nut | 2 pc |

| N283308 | Screw, flange | 2 pc |

| 03H2070 | Bolt, round head | 8 pc |

| 19M7720 | Screw, hex | 2 pc |

| A105392 | Spiked seed closing wheel | 2 pc |

| A97699 | Instructions, dealer download | 1 pc |

AA97392

| A105410 | Deflector, seed firmer tab | 8 pc |

| A107506 | Washer, special | 32 pc |

| A109343 | Seed boot, left hand | 4 pc |

| A109344 | Seed boot, right hand | 4 pc |

| A110307 | Closing arm spring, left hand | 4 pc |

| A110308 | Closing arm spring, right hand | 4 pc |

| A31869 | Locknut | 8 pc |

| AA88056 | Press wheel assembly | 8 pc |

| E55662 | Nut, 3/8 | 32 pc |

| N280653 | Washer | 8 pc |

| N283804 | Opener disk | 8 pc |

| N283976 | Nut, U-nut | 8 pc |

| N283308 | Screw, flange | 8 pc |

| 03H2070 | Bolt, round head | 32 pc |

| 19M7720 | Screw, hex | 8 pc |

| A105392 | Spiked seed closing wheel | 8 pc |

| A117632 | Instructions, ProSeries | 1 pc |

ProSeries seed opener kit

ProSeries seed opener kit

NOTE: Kits are subject to change.

Specs & Compare

Key Specs | N543F Current Model |

| Working widths | 13.1 in. 43 ft |

| Spacing | Seed spacing - 254 mm 10 in. Separate fertilizer - 508 mm 20 in. |

| Number of ranks | Two seed ranks and one separate fertilizer rank |

| Openers | Style Seed, ProSeries™ single-disk blade - 45.72 cm 18 in. Fertilizer, single-disk blade - 45.72 cm Rank lock-up Front, middle, and rear Diameter 45.72 cm 18 in. Down pressure Hydraulic |

Sizes | |

| Working widths | 13.1 m 43 ft |

| Spacing | Seed spacing - 254 mm 10 in. Separate fertilizer - 508 mm 20 in. |

| Number of ranks | Two seed ranks and one separate fertilizer rank |

| Number of sections | Three |

Dimensions | |

| Transport height | 4.83 m 15.83 ft |

| Transport width | 5.59 m 18.33 ft |

| Road clearance | 21.59 cm 8.5 in. |

| Overall length | 8.81 m 28.92 ft |

| Centerframe width | 4.62 m 15.17 ft |

| Centerline of mainframe wheel support tube to centerline of wing wheel support tubes | |

| Weight before ballast | 14,100 kg 30,900 lb |

| Available ballast | Main - up to 14 suitcase weights each at 45.4 kg 100 lb Each wing - 6 suitcase weights each at 45.4 kg |

| Frame | Cross members 102 x 152 mm 4 x 6 in. End tubes 51 x 152 mm 2 x 6 in. Hitch 76 x 152 mm 3 x 6 in. |

| Lateral frame clearance, opener to opener | |

| Clearance from rank to rank | 134.11 cm 52.8 in. |

| From ground to top of lid | |

| From ground to platform | |

| From ground to top of safety rail | |

| From ground to top of lights | |

Tires | |

| Mainframe standard | (8) 11L-15, I-1 12PR |

| Mainframe bolt pattern | Duals with eight-bolt wheels |

| Wings standard | (8) 11L-15, 10PR |

| Wings bolt pattern | Duals with six-bolt wheels |

| Centerframe tires and wheels | |

| Wing tires and wheels | |

| Wheel spacing, center frame | |

Openers | |

| Style | Seed, ProSeries™ single-disk blade - 45.72 cm 18 in. Fertilizer, single-disk blade - 45.72 cm |

| Rank lock-up | Front, middle, and rear |

| Disk | Diameter 45.72 cm 18 in. Angle Seed at 7 degree (angle) Fertilizer (dry only) at 5 or 7 degree (angle) Single blade with beveled edge |

| Down pressure | Style Active hydraulic downforce 10-in. space 75 to 181 kg 165 to 400 lb Hydraulic |

| Depth control | Description Semi-pneumatic Gauge wheel size Standard - 11.43 x 40.64 cm 4.5 x 16 in. Optional - 7.62 x 40.64 cm 3 x 16 in. Range 1.27 to 8.89 cm 0.5 to 3.5 in. Increments 0.64 cm 0.25 in. Gauge wheel beside disk |

| In-Furrow press wheel | Material Rubber-face press wheel Packing force 2.3 to 21 kg 5 to 45 lb Tapered - 2.54 x 22.86 cm 0.75 x 9 in. |

| Furrow closing | Description Trailing wheel on vertical 15 degree (angle) Size 2.54 x 30.48 cm 1 x 12 in. Material Cast iron Down force 12 to 20 kg 26 to 43 lb Yes |

| Double-Shoot capable | Yes - front ranks apply fertilizer |

Seed Metering | |

| Description | |

| Crops | |

| Max Volumetric Seeding Rates - Barley | |

| Max Volumetric Seeding Rates - Oats | |

| Max Volumetric Seeding Rates - Rice | |

| Max Volumetric Seeding Rates - Milo/Sorghum | |

| Max Volumetric Seeding Rates - Soybean | |

| Max Volumetric Seeding Rates - Wheat | |

| Metering Drive Type | |

Seed Storage | |

| Tank Description | |

| Total Tank Capacity | |

| Tank Fill Screen | |

| Tank Scales | |

| Seed Distribution | |

| Type | |

| Blower | |

| Blower drive type | |

| Distribution hose size | |

Equipment compatibility (at 1.5 in. seeding depth and 8 mph) | |

| Tractor drawbar power required, 7.5-in (19.1 cm) models | |

| Tractor drawbar power required, 10-in (25.4 cm) models | |

| Tractor drawbar power required, 15-in (38.1 cm) models | |

Tractor requirements | |

| Minimum number of SCV's | |

| Hydraulic Power Beyond | |

| Minimum hydraulic capacity | |

| Minimum electrical capacity | |

Additional information | |

| Tool-mounted alternator | |

| Implement harness connection, 56 VDC | |

| Implement harness connection, 12 VDC | |

| Operator interface | |

| Four-section seed on/off | |

| Fast start/Quick start | |

| Seed blockage sensor per row | |

| Date collected |